When products become more and more similar, individuality must come from design. Especially for packaging, but also for technical parts, extraordinary solutions are required. We develop your idea entirely up to the finished plastic part and offer support in the following important steps.

We accept your challenge!

Design & CAD

From vision to paper

Your vision regarding shape, color, material and functionality becomes reality with the know-how of our experts. The success story of your products begins with our experienced CAD team. In close cooperation, we merge your idea with what is technically feasible, most economical and most sustainable into 2- or 3-dimensional proposals.

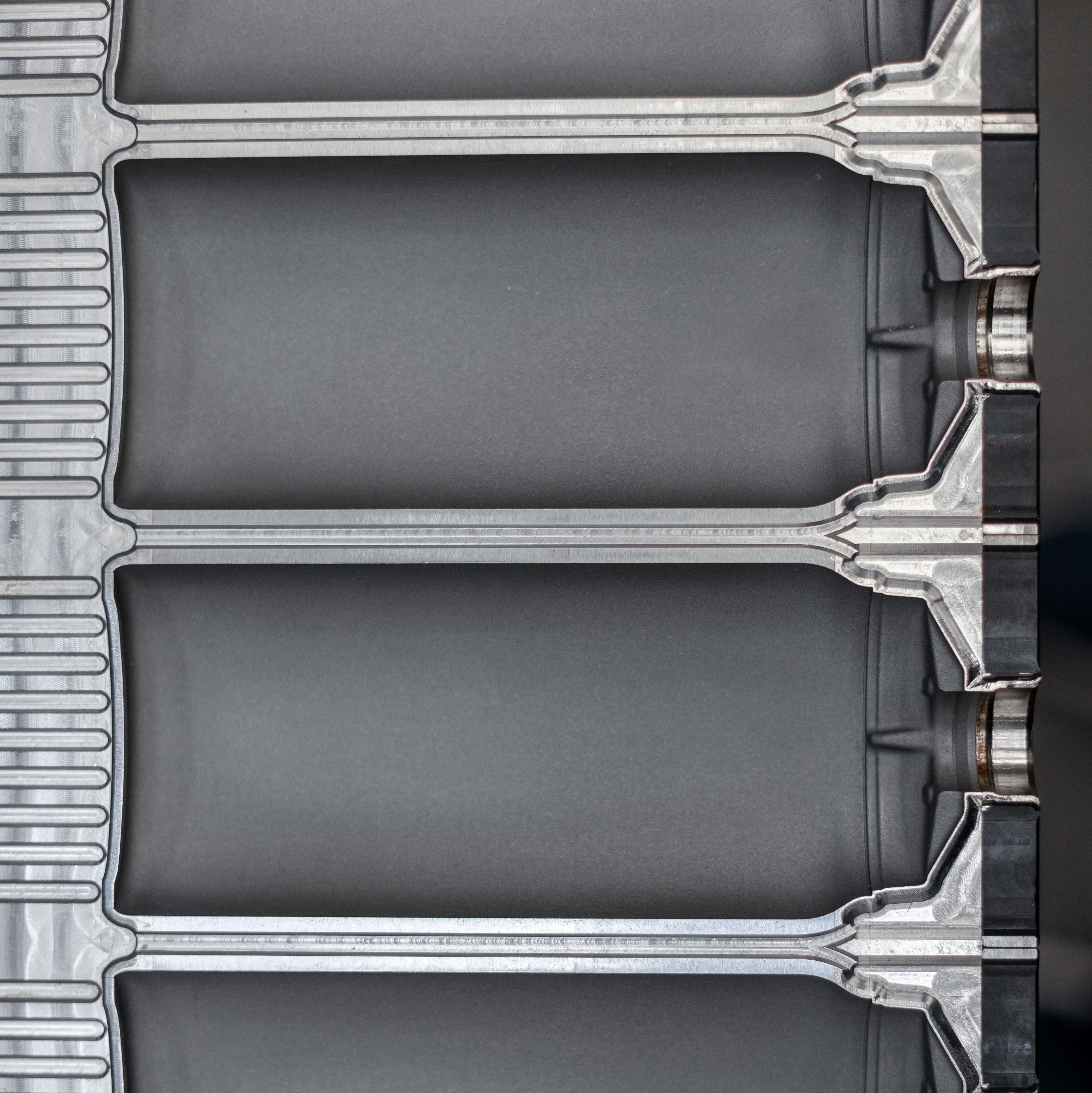

Toolmaking

From paper to steel

After determining the best manufacturing process, our in-house toolmaking department transforms your favored design proposal into steel.

With the most modern technical equipment, our qualified specialists can operate largely independently of external suppliers and therefore respond quickly and flexibly to all customer requirements.

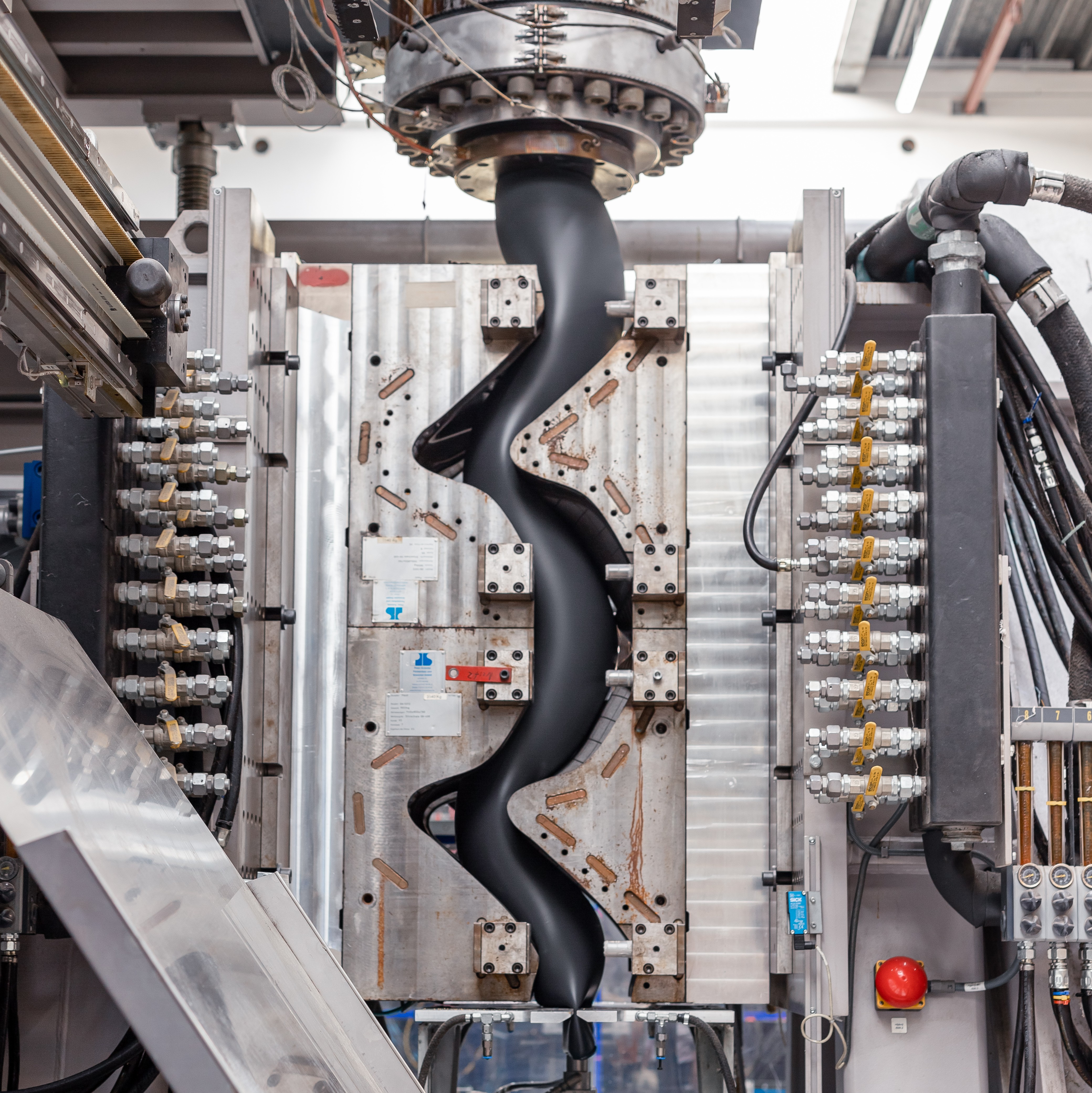

Production

From steel to plastic part

After completion of the pilot or series tool, the exciting stage of sample production begins - your idea becomes reality. At this stage, aesthetics, quality, function and producibility are combined by our experienced process mechanics. With our advanced machinery, which we are constantly developing, we are able to realize the most demanding innovations and shape your idea into a winner.

Fixture construction

From plastic part to packed plastic part

The development is completed by our innovative fixture construction department. Here, specific peripheral equipment is created for the partial automation of our assembly lines. This allows us to achieve an economically beneficial production and ideal packaging of the plastic parts for subsequent transport.